Automatic Vacuum Forming Machines

a leading destination for vacuum forming machines, offering unparalleled affordability, advanced technology, and tailored solutions.Whether you’re a startup or an established manufacturer, exploring options from Chinese suppliers can enhance your production capabilities.

Thick Vacuum Forming Machine

- Adopts Plc Control System and touch screen.

- PVC,ABS,PC,PE Sheet (1-10mm).

- Heat system: using up and down heat system, Could get high temperatuer in Very Short time.

- Max Forming Area: 2500*2200*1000(mm).

- Aircraft tray tables, window shade liners, galley pans, seat backs, miscellaneous interior covers.

- Truck bedliners,truck caps,tonneau covers,bug shields,rain guards, floor mats,dash kits.

Single

Auto Loading

Loading & Unloading

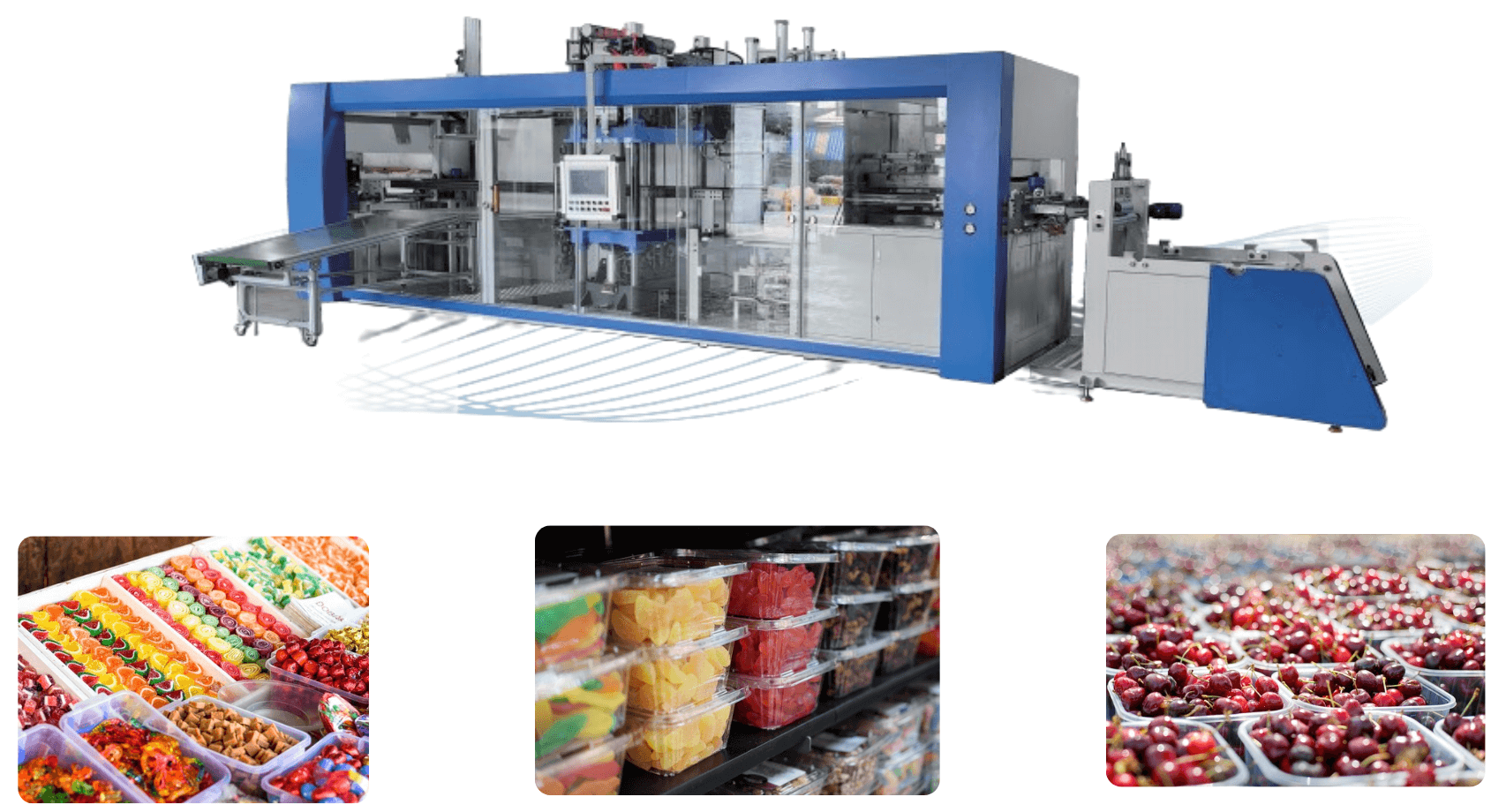

Automatic Vacuum Forming Machine

The vacuum forming process involves several key steps:

Heating: A plastic sheet is warmed until pliable.

Forming: The softened material is drawn tightly against a mold using vacuum pressure.

Cooling and Trimming: Once cooled, the formed part is removed and trimmed to its final shape.

Thin Vacuum Forming Machine

- Usually for Thin plastic (0.2-1.5mm) forming,Vacuum forming, commonly known as thermoforming machine, is a simplified version of thermoforming.

- whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying vacuum between the mold surface and the sheet.

- vacuum forming machine, also known as thermoplastic forming machine, is a machine that absorbs thermoplastic coil materials such as PVC, PE, PP, PET, HIPS and other thermoplastic rolls into various shapes of high-grade packaging decoration boxes, frames and other products.

- By using the vacuum suction produced by the vacuum pump, the heated and softened thermoplastic sheets such as PVC and PET are molded into vacuum covers, blister trays, bubble shells and so on.

Food Tray

Packaging

Electric

Small Vacuum Forming Machine

- Small Automatic vacuum forming machine.

- PVC,PET.etc roll film .

- Heat system: using up independent heat system.

- Max Forming Area: 560*610*150(mm).

- blister packaging, fruit tray,biscuit boxex,egg tray,moon cake packaging trays.

Automatic

Manual

Application

Advertising Vacuum Forming Machine

Samples

Covers

3D Letters

Why China Vacuum Forming Machine?

How to Choose a Vacuum Forming Machine?When selecting a machine, consider:

Size and Capacity: Ensure it fits your production needs.

Material Compatibility: Check if it supports the plastics you use.

Automation Level: Decide between manual, semi-automatic, or fully automatic.

Budget and Maintenance: Balance initial costs with long-term upkeep.