Plastic Crusher — P Series

Plastic Crusher Machine P Series are good for varies plastic materilas with common thickness such as PVC,PET,PS,ABS sheet, and plastic board, plastic pipes,plastic bottles and other plastic packaging materials.This kind of plastic crusher machine sells very well.

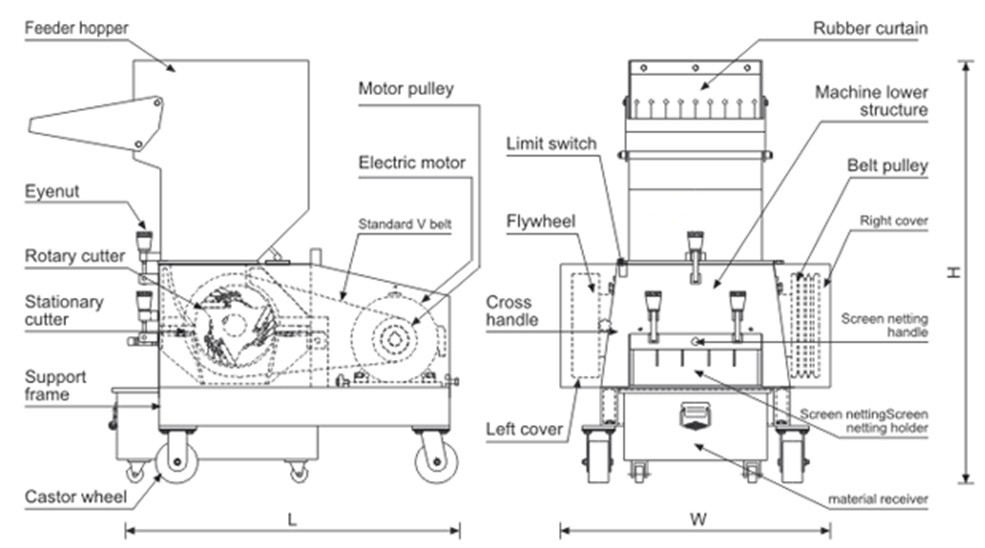

Structure:

Specifications:

| Model | CP230 | CP300 | CP400 | CP500 | CP600 | CP800 |

| Chamber | 230*200 | 300*200 | 410*235 | 515*290 | 610*320 | 815*470 |

| Output | 100-150 | 150-200 | 250-300 | 300-350 | 350-400 | 450-600 |

| S-Blade | 2pcs | 2 | 2 | 2 | 4 | 4 |

| R-Blade | 6pcs | 9 | 12 | 15 | 18 | 24 |

| Power | 4KW | 5.5 | 7.5 | 11 | 15 | 22/30 |

| HP | 5 | 7.5 | 10 | 15 | 20 | 30-40 |

| Size | 95*62*120 | 100*72*129 | 124*94*163 | 139*107*184 | 175*143*228 | 196*171*277 |

| Weight | 290KG | 440KG | 500KG | 900KG | 1100KG | 2000KG |

You May be Also Interested in Relative Products:

|  |  |

| V Series Plastic Crusher | J Series Plastic Crusher | S Series Plastic Crusher |

A plastic crusher is a machine designed to reduce plastic materials into smaller pieces, making them easier to handle, recycle, or dispose of. These machines are essential tools in industries that deal with plastic waste, including recycling facilities, manufacturing plants, and environmental organizations. By breaking down plastic waste into manageable sizes, plastic crushers contribute significantly to waste management and sustainability efforts.

How Does a Plastic Crusher Work?

Plastic crushers operate through a straightforward yet efficient process:

- Feeding: Plastic waste, such as bottles, containers, or industrial scraps, is fed into the crusher.

- Shredding: Rotating blades inside the machine cut and grind the plastic into smaller pieces.

- Output: The processed plastic is collected in a bin or discharged for further use, such as recycling or energy recovery.

Most plastic crushers are equipped with adjustable blades, enabling them to handle a variety of plastic types and sizes.

Types of Plastic Crushers

Single-Shaft Crushers

- Best for light to medium-duty applications.

- Suitable for small-scale recycling or processing soft plastics like packaging materials.

Double-Shaft Crushers

- Designed for heavy-duty applications.

- Capable of handling hard plastics, such as PVC pipes and automotive parts.

Granulators

- Focused on producing uniform-sized granules for recycling purposes.

- Ideal for preparing plastics for injection molding or extrusion processes.

Industrial Crushers

- Used in large-scale operations to process significant volumes of plastic waste.

- Equipped with high-power motors and robust blades for maximum efficiency.

Applications of Plastic Crushers

Plastic crushers are versatile machines used across a range of industries:

- Recycling: Reducing plastic waste into granules for reprocessing into new products.

- Manufacturing: Managing plastic scraps generated during production processes.

- Environmental Management: Assisting in the reduction of plastic pollution by breaking down waste for proper disposal.

- Industrial Use: Preparing materials for further processing in construction, automotive, and packaging industries.

Benefits of Using a Plastic Crusher

Promotes Recycling

Plastic crushers play a crucial role in the recycling process by breaking down waste into reusable materials. This helps conserve resources and reduces environmental impact.

Reduces Waste Volume

By shredding plastic into smaller pieces, crushers minimize the volume of waste, making storage and transportation more efficient.

Cost-Efficient

Using a plastic crusher reduces disposal costs and generates raw materials for manufacturing, making it a cost-effective solution for businesses.

Supports Sustainability

Plastic crushers contribute to sustainable waste management practices by enabling the reuse of materials, reducing landfill waste, and lowering greenhouse gas emissions.

Key Features of a Plastic Crusher

- Durable Blades: High-quality, sharp blades that can handle various types of plastics.

- Customizable Settings: Adjustable speed and blade configurations for different materials.

- Safety Features: Emergency stop buttons and protective covers to ensure operator safety.

- Compact Design: Machines are available in sizes to fit both small-scale operations and industrial facilities.

Materials That a Plastic Crusher Can Process

- Polyethylene Terephthalate (PET): Commonly used for bottles and containers.

- Polypropylene (PP): Found in packaging, textiles, and automotive parts.

- High-Density Polyethylene (HDPE): Used for pipes, crates, and milk jugs.

- Polyvinyl Chloride (PVC): Found in construction materials like pipes and flooring.

Challenges in Plastic Crushing

While plastic crushers are efficient, they can face challenges such as:

- Material Contamination: Non-plastic debris can damage the machine or affect the recycling process.

- Blade Wear and Tear: Frequent use may require regular maintenance and blade replacement.

- Energy Consumption: Larger machines may consume significant energy, increasing operational costs.

Innovations in Plastic Crushers

Recent advancements have improved the efficiency and functionality of plastic crushers:

- Smart Sensors: Detect material types and optimize crushing processes.

- Energy Efficiency: Machines designed to consume less power while maintaining performance.

- Eco-Friendly Options: Crushers compatible with biodegradable plastics and sustainable operations.

Conclusion

A plastic crusher is an indispensable tool in waste management and recycling industries. By reducing plastic waste into reusable forms, these machines support sustainability, enhance resource efficiency, and promote eco-friendly practices. Whether for small-scale recycling or large industrial operations, investing in a plastic crusher is a step toward a greener future.