Plastic thermoforming resources

What is thermoforming?

Thermoforming is a plastic manufacturing process where a thermoplastic sheet is vacuum formed or pressure formed into a specific shape.

Plastic Thermoforming Process:

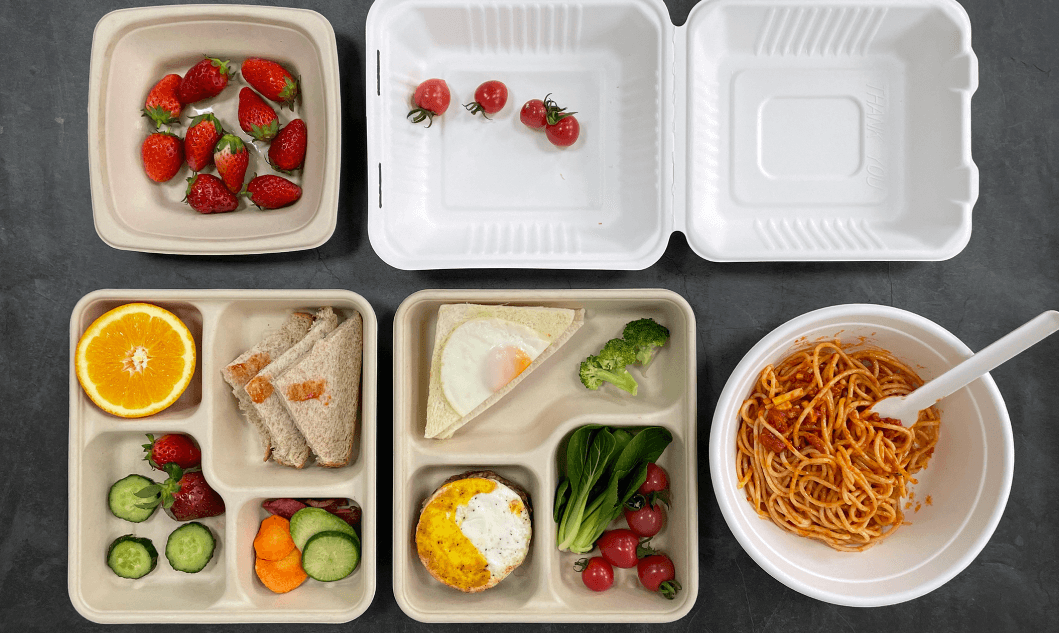

thin thermoforming process: Roll Sheet such as PVC,PET material— Heat—Forming—Cutting—stacking –packaging

PVC film: easy to heat and can be sealed with a sealing machine and high-frequency edge sealing. It is the main raw material for producing transparent plastic products. PVC sheet is a widely used and popular material. PVC film can be divided into environmental protection and non-environmental protection. It can be made into transparent, colorful, anti-static, gold-plated, flocking and other blister packaging products.

PET film:It has good toughness and is a new type of material developed in recent years. With its excellent toughness, high strength, high transparency, and recyclability, it is easy to burn and does not produce harmful gases when burned. It is an environmentally friendly material and gradually banned PVC, but the price is high. It is suitable for high-end blister products.

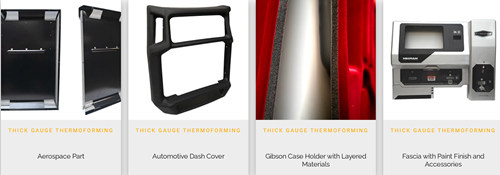

Thick Thermoforming Process: Cut sheet with size 1*1M or 1*2M—-Heat—Forming—- CNC trimming—-install

Materials of Thermoforming:

• Acrylic (PMMA)

• Acrylonitrile Butadiene Styrene (ABS):One of the most widely used thermoplastic materials,due to its impac strength,rigidity and abrasion resistance.

• Cellulose Acetate

• Low Density Polyethylene (LDPE)

• High Density Polyethylene (HDPE)

• Polypropylene (PP)

• Polystyrene (PS)

• Polyvinyl Chloride (PVC)

Global Thermoforming Market

Thermoforming Machines Manufacturers:

- Adopts Plc Control System and touch screen.

- PVC,ABS,PC,PE Sheet.etc (2-10mm).

- Heat system: up and down heat system.

- Max Forming Area: 4000*2500*1000(mm).

- Aircraft tray tables, window shade liners, galley pans, seat backs, miscellaneous interior covers.

- Truck bedliners,truck caps,tonneau covers,bug shields,rain guards, floor mats,dash kits.

- Headliners, cargo liners, door watershields, dash insulators, flooring, package trays/shelves.

- Bumper fascias, running boards, spare tire covers, ground effects, wheel wells, gas tanks.