- No matter what kind of toothbrush design you sell—and there are more today than ever before—your business won’t get very far without proper packaging. However, packaging is far from enough on its own. Just like anything in business, if there’s a way to do it better, you must start doing it that way.

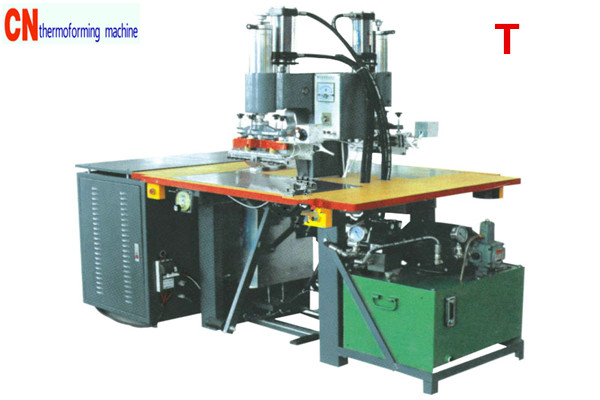

- Otherwise, you could lose sales and/or profits while your competitors scoop up market share. One important way to address your packaging needs is by using machines like the CN-300A or CN-500A. They can accommodate just about any toothbrush design and do it better than your current method.

Blister Packaging

- For one thing, these machines produce blister packaging that can be used for any kind of toothbrush design you sell now or may decide to in the future. This means they’re perfect for traditional brushes, electric models, interdental instruments, and even Sulcabrushes.

- On top of that, they offer a number of other benefits. They’re convenient to shelve and easy to open. Customers can see the entirety of the brush before buying. Still, the plastic bubble formed around it offers plenty of protection for your merchandise.

- The list goes on and on, but hopefully it’s obvious why blister packaging has become the industry standard. Plus, despite all these benefits, this packaging option is incredibly affordable for any toothbrush design.

Save Even More

- Now let’s talk about what happens when you combine blister packaging with machines like the CN-300A or CN-500A. First, you’ll save even more on this type of packaging.

- For one, not having humans handle the process saves you on having to pay them. It also saves you on the cost of human error. These machines don’t suffer the effects of lethargy no matter how long you have them operating for and they are incapable of making mistakes.

- They also won’t waste materials. Even the most skilled of your assembly line workers can’t package toothbrushes with the precision of one of these machines.

- Either model only needs five millimeters of excess material around the sides to clamp down and seal the packaging shut. So each time you sell a toothbrush, you get to keep more of the money because you’re not losing it on wasted plastic.

Package More

- Depending on the toothbrush design you specialize in, you’re probably seeing more and more sales. So it would make sense that you’d want to sell more and more units. The problem is that means packaging more and more of them and, like we just said, that costs you more money.

- Trying to scale up will, therefore, only mean greater amounts of overhead.

With the CN-300A or CN-500A Automatic toothbrush packaging Machine on your side, though, scaling up may not even be necessary. That’s because they can process packaging far quicker than you’re doing it now.

- Plus, even if you do need more machines, as you’ve already seen, it won’t mean wasting money on the investment.

If you’re in the toothbrush business, that should mean a lot of revenue in the future. Protect it from unnecessary overhead, then, with machines like the CN-300A or CN-500A and continue to grow with demand.