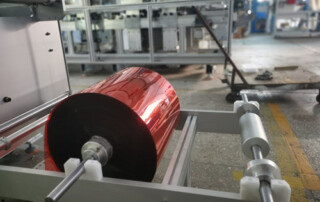

CN-300C Blister Forming Machine

Automatic Blister Forming Machine

| Model | CN-300C |

|---|---|

| Max Forming Area | custom made |

| Cutting Frequency | 15-20times/min |

| Air Compressed | 6-8 bar |

| Power | 380V/50Hz/5.0KW |

| Machine Size(L*W*H) | 5000*800*1800MM |

| Weight | 1100KG |

Blister Forming Machine

Saving Labor: CN-300C only need 1 worker, Save labour cost than traditional way.

High Speed: CN-300C 3-4s/mold,forming area custom made according the products.

Competitive Price: Compared with Germany or Korean Machines ,Our price is very very competitive with good quality and same function.

The blister forming machine, also called the thermoforming machine,is a machine that sucks the heated plasticized PVC, PE, PP, PET, HIPS and other thermoplastic plastic coils into various shapes of advanced packaging boxes, frames and other products. Using the vacuum suction force generated by the vacuum pump, the heated and softened PVC, PET and other thermoplastic plastic sheets are blister-molded into various shapes of vacuum covers, blister trays, blisters, etc.

Machine structure: The main structure of the machine is composed of feeding,upper and lower electric heating furnace,upper mold forming,cutting, placing film and equipped with vacuum device, etc. ;

Blister forming: It is the blister that we often talk about. A Thermoforming blister machine is used to absorb the heated and softened plastic hard sheet on the surface of the mold. After cooling, it forms a concave-convex shape of the plastic.

Blister cutting: After blister molding, the plastic products are cut into individual products by punching the forming sheet.

Advantages

- Blister Forming,Cutting Inline

- PLC Control System And Colorful Touch Screen

- Up And Down Heat elements to save heating time

- Servo Motor to keep accurate

- SMC Japan Brand Pneumatic components

CN-300C Running Video