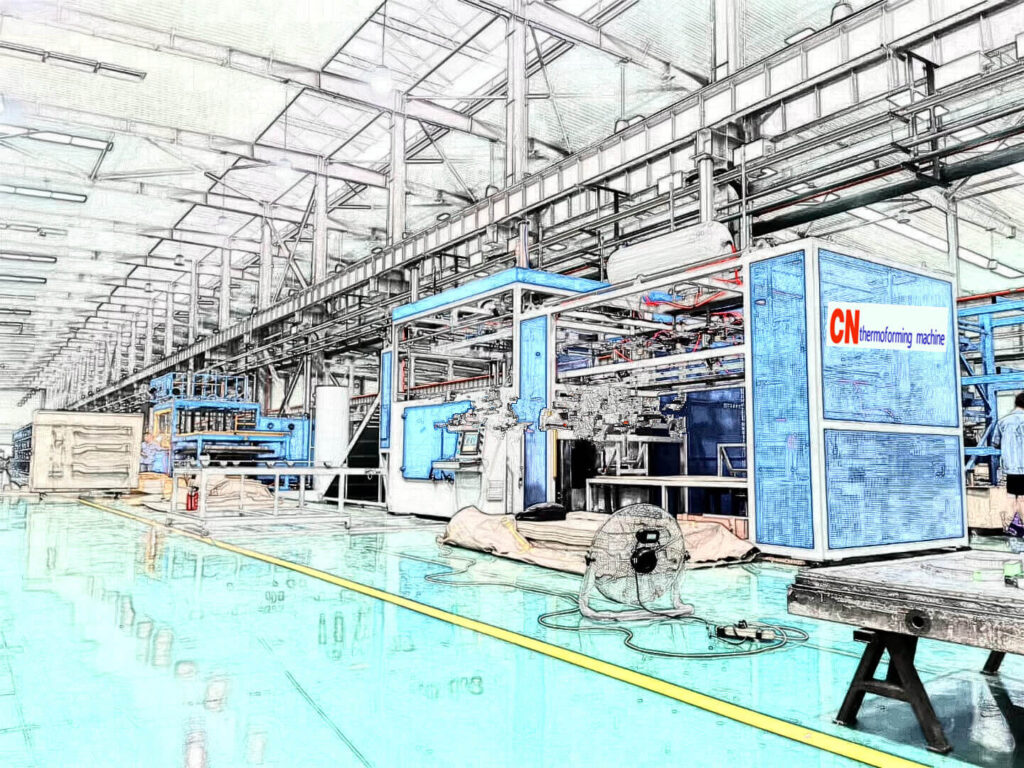

large vacuum forming machine

A large vacuum forming machine is designed to handle oversized plastic sheets and produce large-scale parts. These machines are ideal for industries requiring substantial, durable components, such as automotive panels, architectural features, and industrial enclosures.

Key Features of Large Vacuum Forming Machines

- Increased Forming Area: Capable of handling larger plastic sheets, often several meters wide.

- High Power and Capacity: Equipped with powerful heating elements and vacuum pumps to evenly form thick, large materials.

- Advanced Control Systems: Includes computerized settings for precise temperature, vacuum pressure, and forming time.

- Multiple Station Capabilities: Many large machines integrate heating, forming, and cooling stations to streamline production.

- Custom Mold Compatibility: Supports intricate and oversized molds, allowing for diverse product designs.

Applications of Large Vacuum Forming Machines

- Automotive and Transportation:

- Large interior panels, bumpers, and dashboard components.

- Parts for buses, trains, and airplanes.

- Industrial Equipment Housings:

- Enclosures for heavy machinery and industrial tools.

- Protective covers and panels for large-scale equipment.

- Architectural and Construction:

- Decorative panels, wall coverings, and signage.

- Skylight and roofing components made from durable plastics.

- Consumer Goods and Retail Displays:

- Large point-of-sale displays, product stands, and shelving units.

Benefits of Using Large Vacuum Forming Machines

- Scalability: Produces large parts in fewer runs, increasing efficiency for big projects.

- Cost-Effectiveness: Lower tooling costs compared to injection molding for large components.

- Material Versatility: Handles thick-gauge materials and a wide range of plastics, including ABS, polycarbonate, and acrylic.

- Durable Output: Creates robust, lightweight components that maintain their shape and structural integrity.

Considerations When Investing in a Large Vacuum Forming Machine

- Space Requirements:

- Ensure the facility can accommodate the machine’s dimensions and sheet sizes.

- Power Needs:

- Larger machines require substantial electrical capacity and proper ventilation.

- Maintenance and Support:

- Factor in ongoing maintenance costs and access to technical support.

- Production Volume:

- Choose a machine that aligns with the expected production scale and cycle times.

Conclusion

Large vacuum forming machines offer unparalleled flexibility and capacity for producing oversized plastic parts. Their ability to handle thick materials, complex molds, and extensive forming areas makes them a cornerstone of many industries, from automotive manufacturing to architectural design. Investing in a large vacuum forming machine ensures efficiency, high-quality results, and scalability for large-scale projects.

In this Article