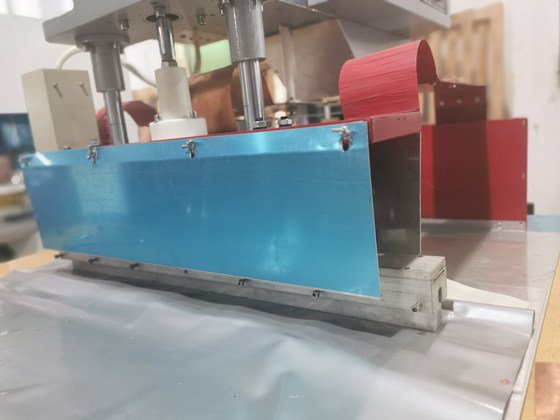

High frequency welding Machine, also known as media or electronic heat fusion welding, the materials applicable for high frequency plastic welding can vary from very thin plastic sheets to the stiff plastic products. The machines are composed by the top platen (electrode) and the lower platen (electrode). You can weld your product by fixing the mold on the top or lower electrodes.other kinds of blister packaging machine price for reference.

It’s suitable for welding Blister&Blister, Blister&Paper card, Paper card&Paper card. Widely used in stationery, toys, electronic products, hardware, cosmetic etc.hf welding is a plastic welding process that utilizes high-frequency electric fields to induce heating and melting of thermoplastic base materials.The electric field is applied by a pair of electrodes after the parts being joined are clamped together.

High frequency is high frequency wave. High-frequency and ultrasonic are two different concepts. High-frequency refers to electromagnetic waves with a frequency greater than 100KHz, and ultrasonic refers to sound waves with a frequency greater than 20 kHz. The welding principle and welding principle of high-frequency waves are also different from ultrasonic waves.To achieve the purpose of welding and welding. High-frequency application fields are wide, so there are high frequency plastic welding machine, high-frequency plastic fusing machines, high-frequency folding box creasing machines, and high frequency welding and cutting machine.

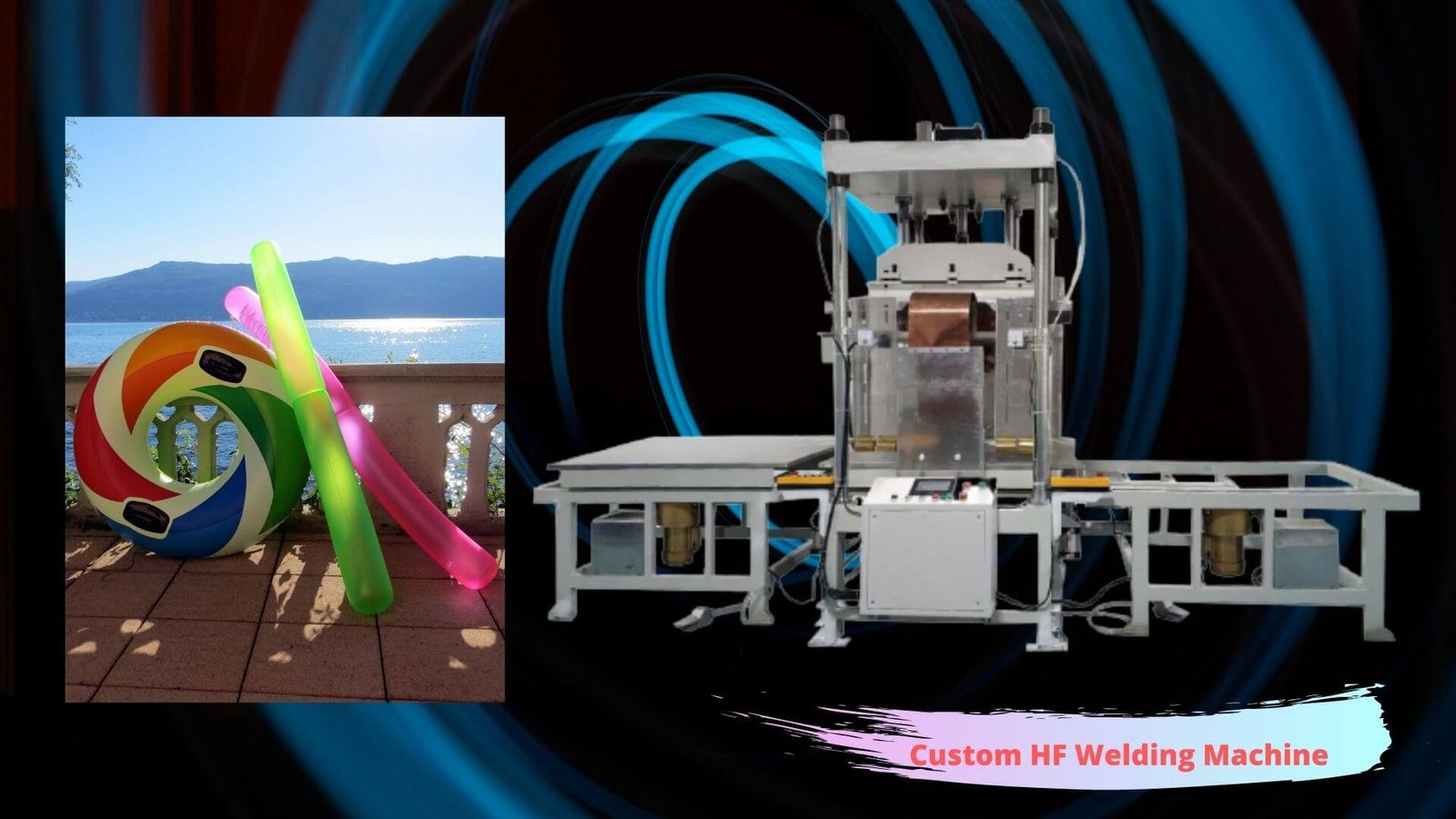

HF Welding & Cutting Machine

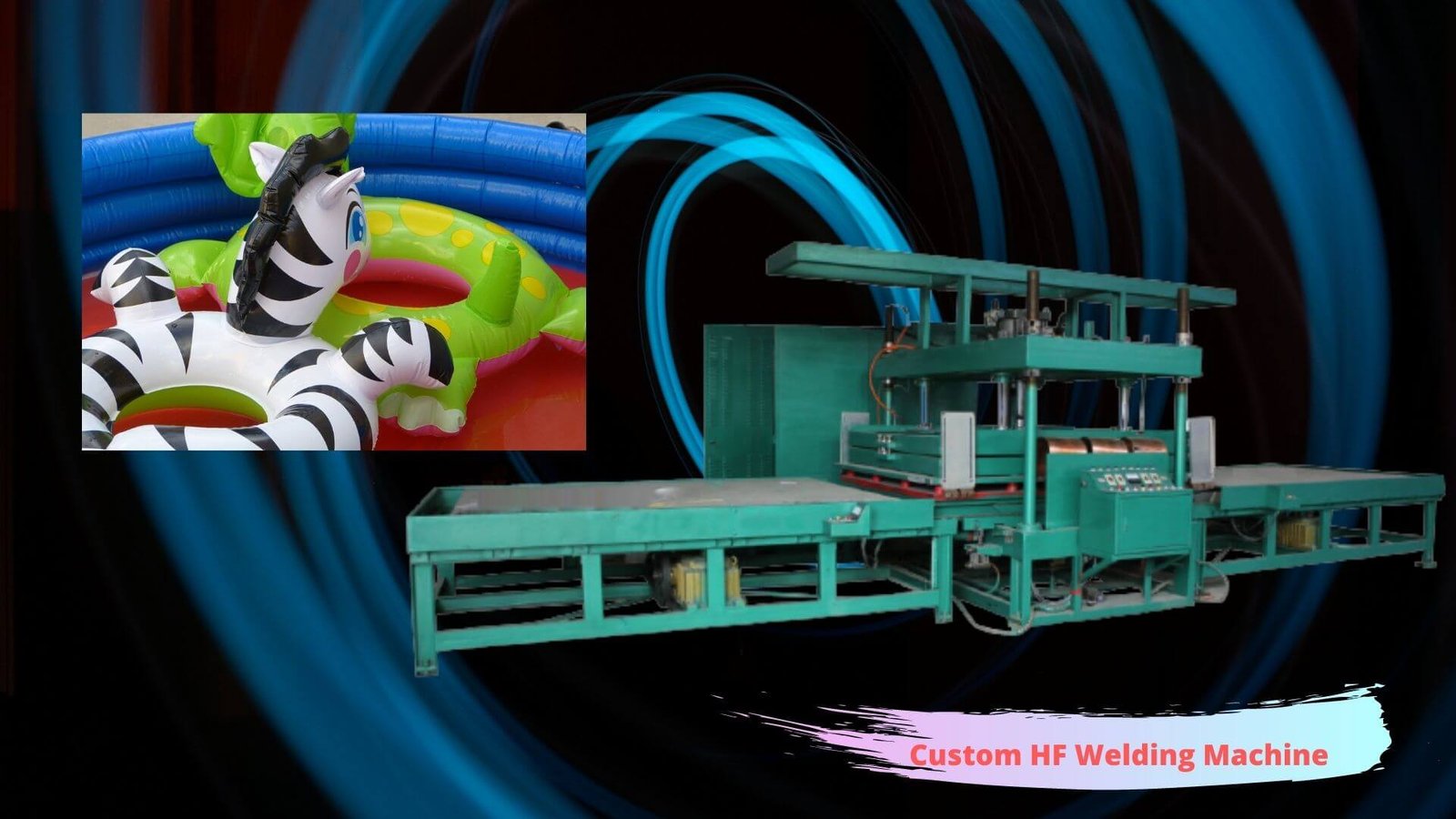

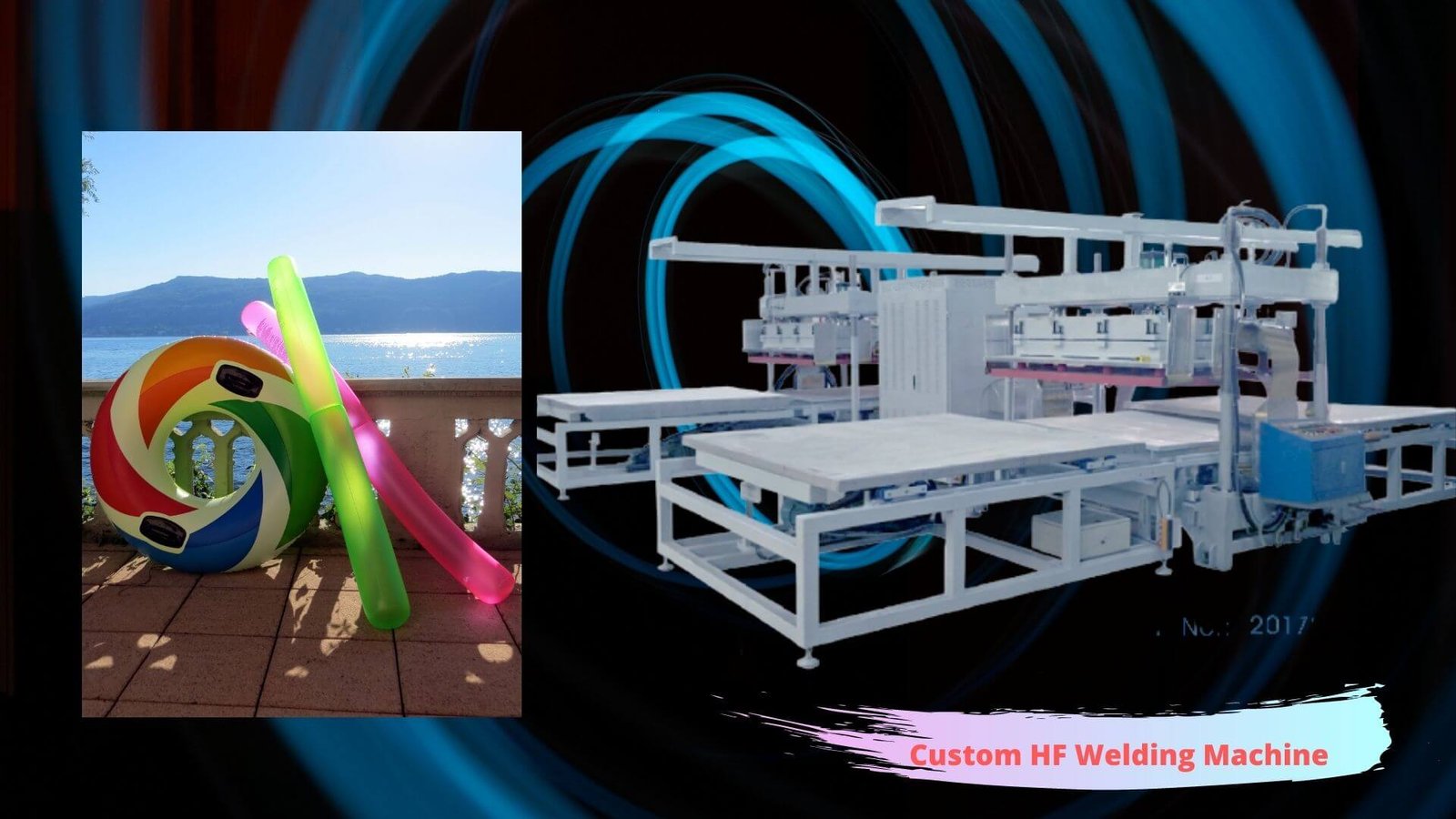

Custom Made HF Welding Machine

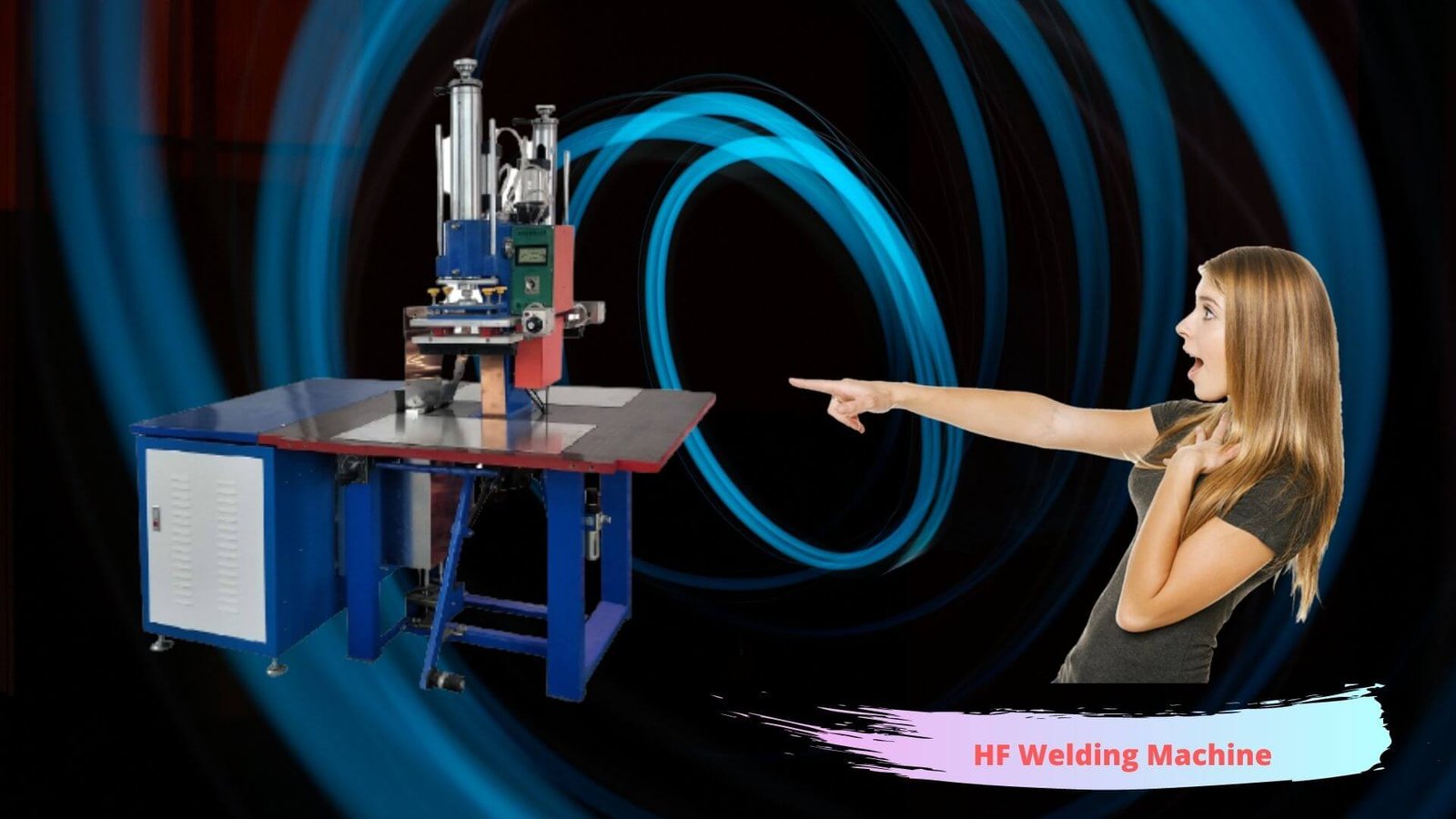

Small HF Welding Machine

Let us take care of all your machine needs.

Custom Made

Reasonable Price

Projects Videos

How does a high frequency welding machine work

High frequency welding works through a combination of electromagnetic waves, heat, and pressure. The process includes:

- Preparation: Materials are positioned between electrodes.

- Welding: High-frequency waves cause the plastic molecules to vibrate and generate heat, softening the material.

- Cooling: Pressure is applied while the material cools, creating a strong bond.

Types of high frequency welding machines

Manual high frequency welding machines

- Operated manually and ideal for small-scale production or prototyping.

Semi-automatic high frequency welding machines

- Combine manual and automated processes, making them suitable for medium-scale production.

Fully automatic high frequency welding machines

- Fully automated with minimal human intervention, ideal for high-volume manufacturing.

Specialized high frequency welding machines

- Designed for specific applications like blister packaging or tarpaulin welding.

Applications of high frequency welding machines

Packaging

- Used to seal blister packs, flexible pouches, and clamshell packaging.

Medical devices

- Commonly used for IV bags, blood bags, and other sterile products.

Automotive

- Produces items like airbags, seat covers, and door panels.

Consumer goods

- Used for products like inflatable toys, raincoats, and stationery.

Industrial

- Joins materials for tarpaulins, conveyor belts, and tents.

Benefits of high frequency welding machines

- Produces strong and durable bonds.

- Creates clean and precise welds.

- Enables fast production cycles.

- Supports a wide range of thermoplastics.

- Reduces environmental impact by eliminating the need for adhesives.

Materials suitable for high frequency welding

- PVC (Polyvinyl Chloride): Widely used for its flexibility and durability.

- PU (Polyurethane): Preferred for medical and automotive applications.

- PET (Polyethylene Terephthalate): Ideal for food packaging.

- EVA (Ethylene Vinyl Acetate): Commonly used in soft and flexible products.

- TPU (Thermoplastic Polyurethane): Known for its elasticity and strength.

Choosing the right high frequency welding machine

- Evaluate production scale: Choose manual, semi-automatic, or automatic models based on your needs.

- Check material compatibility: Ensure the machine can weld your chosen materials.

- Consider electrode configuration: Ensure compatibility with your product sizes and shapes.

- Prioritize safety: Look for machines with overload protection and emergency stop features.

- Assess durability: Choose machines with easy-to-maintain components.

Maintenance tips for high frequency welding machines

- Regularly clean electrodes and surfaces to prevent buildup.

- Lubricate moving parts to reduce wear.

- Inspect components for damage or wear and replace as necessary.

- Check and calibrate power settings for optimal performance.

- Perform routine maintenance to extend machine lifespan.

Conclusion

High frequency welding machines are vital for industries requiring precision, durability, and efficiency in bonding thermoplastics. They serve diverse applications, from packaging to medical devices, and offer eco-friendly solutions by eliminating adhesives. Investing in the right machine and maintaining it properly can significantly enhance manufacturing productivity and product quality.

In This Article

- HF Welding Machines

- Let us take care of all your machine needs.

- How does a high frequency welding machine work

- Types of high frequency welding machines

- Applications of high frequency welding machines

- Benefits of high frequency welding machines

- Materials suitable for high frequency welding

- Choosing the right high frequency welding machine

- Maintenance tips for high frequency welding machines

- Conclusion